University of Plymouth Energy & Sustainability Lab

The University of Plymouth is looking to reinforce its reputation as an innovative centre of excellence for engineering research, teaching and learning. The new Engineering and Design facility (NEDF) has been constructed on the western edge of the main Plymouth campus and provides a new home for the specialist laboratories and teaching facilities of the School of Engineering, Computing and Mathematics and the School of Art, Design and Architecture.

The Challenge

The Energy and Sustainability Laboratory has two roles:

- To provide engineering students with practical experience, utilising experimentation and analysis using the latest laboratory equipment, instrumentation, and data capture techniques.

- To provide a modern facility for teaching, research and commercial applications, covering a broad range of energy related subject areas.

Hands on experimental equipment allowing students to operate, observe and evaluate the working principles of differing energy engineering disciplines.

GUNT Technology’s focus was on traditional and renewable energies throughout 2024, so we were delighted to help Dr Anthony Robotham bring his vision to life within the New Energy Lab.

Our challenge was to meet the practical requirements set out by the university. We are immensely proud to have been involved with Dr Robotham, his team, and the University in helping to create an engineering centre of excellence.

The Solution

The solution proposed was to equip the brand-new laboratories with energy equipment to meet the high standards set by the university, bringing their facilities up to date with the latest in didactic equipment supported by the latest software and extensive teaching/learning resources.

Our sales engineers were on-site for the delivery and installation, supported by our Engineers from Hamburg who commissioned the equipment and provided extensive product training.

Today the facility is a show-piece of education excellence, providing students not only with equipment to enthuse and excite their learning experience but an environment that is focused and calming in which to work, supported by staff that are passionate about engineering.

GUNT continue to support the University of Plymouth with their vision.

Benefits

- Brand new equipment for a brand new lab

- Complete refurbishment of the new Engineering and Design facility (NEDF)

- Provides a new home for the specialist laboratories and teaching facilities

- New Engineering courses to increase student intake

- Open to students and organisations

Visit the University of Plymouth news pages to see HRH Duke of Gloucester open this brand new state-of-the-art facility.

Equipment

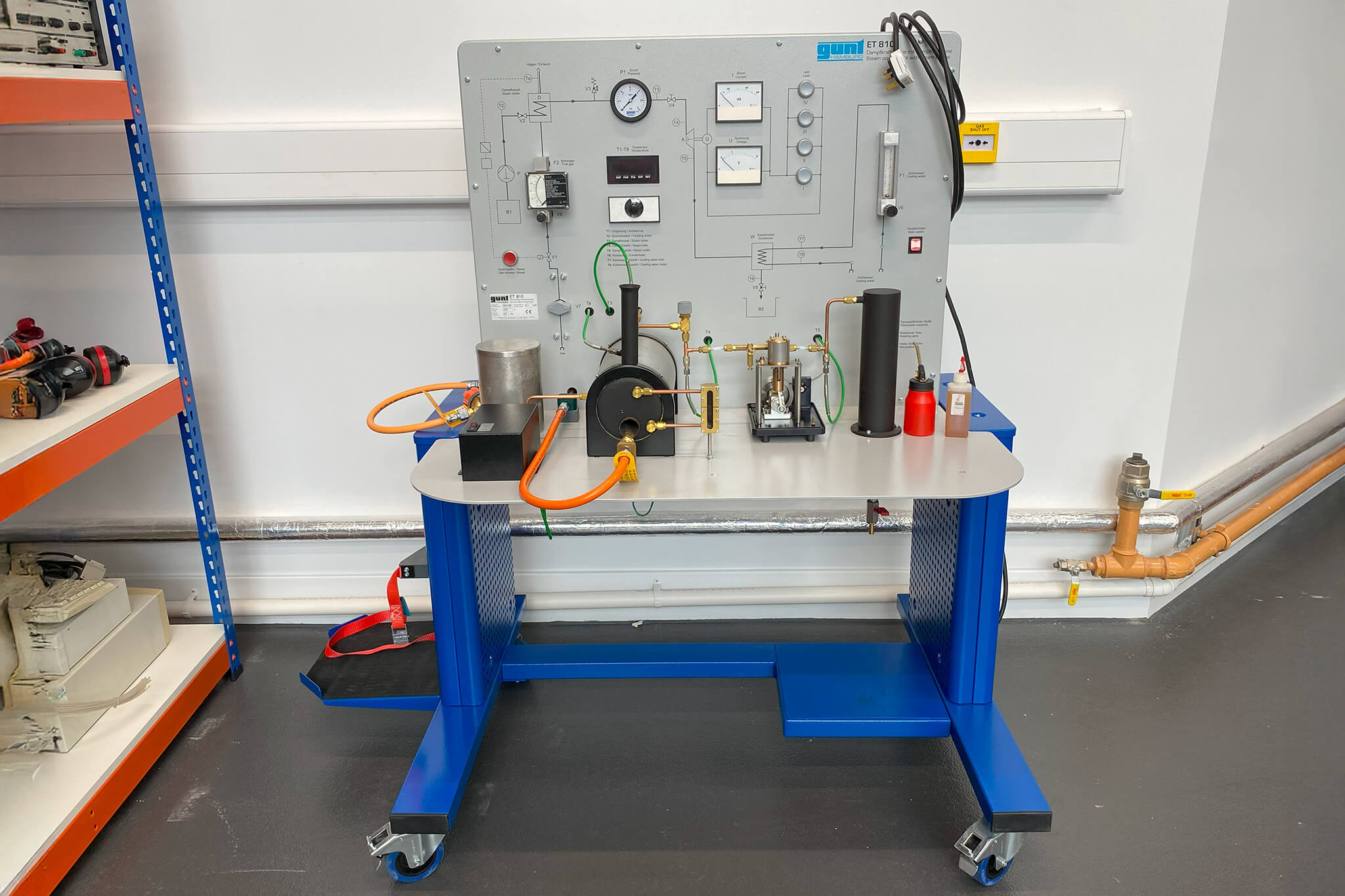

- CT 159 Modular test stand for single-cylinder engines, 3kW

- CT 159.01 Electronic engine indicating system for CT 159

- CT 159.02 Exhaust gas analysing unit

- CT 159.03 Pressure transducer and TDC sensor for CT 150

- CT 159.04 Pressure transducer and TDC sensor for CT 151

- CT 159.05 Pressure transducer and TDC sensor for CT 153

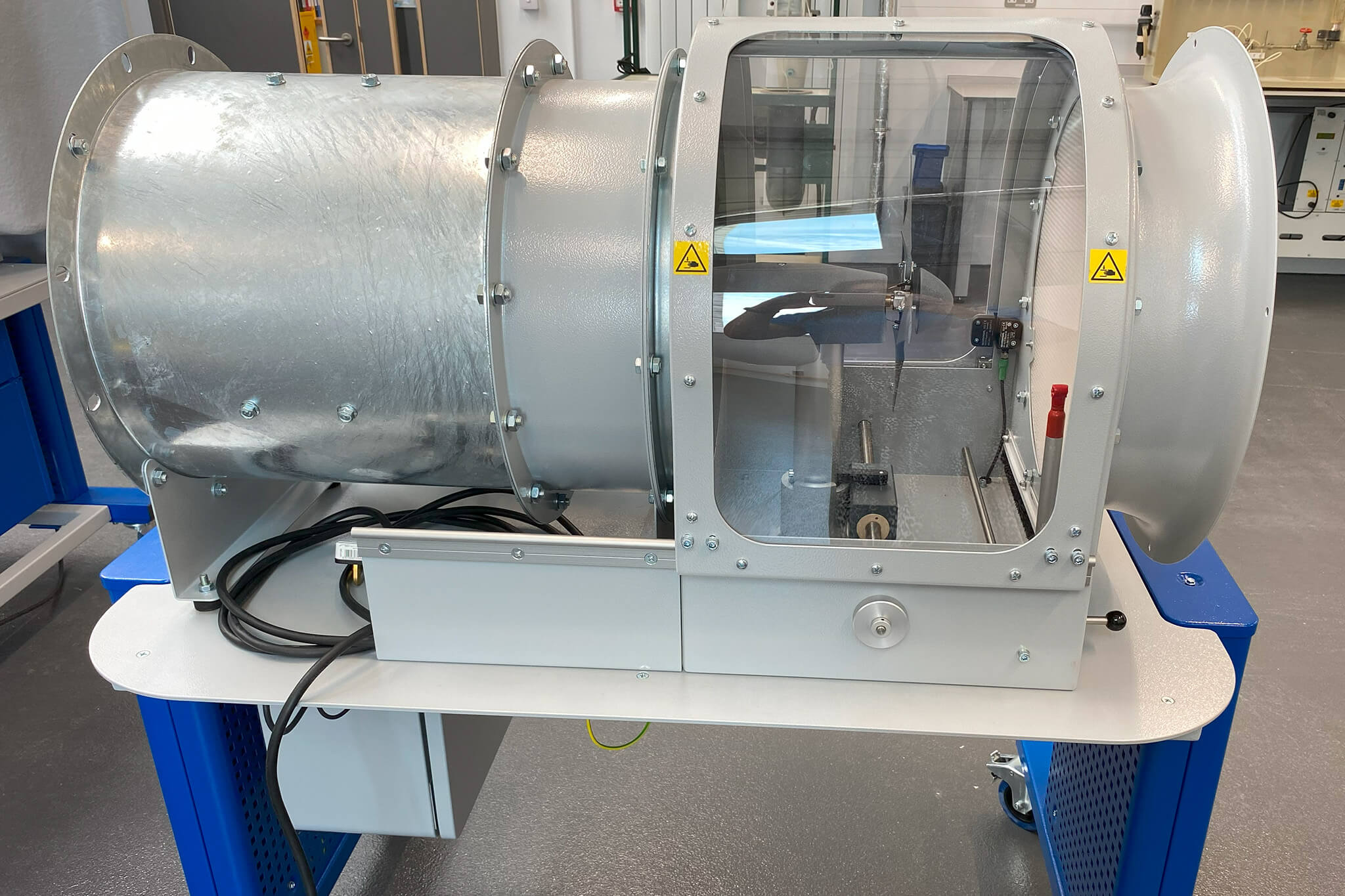

- HM 170 Open wind tunnel

- HM 170.01 Drag body sphere

- HM 170.02 Drag body hemisphere

- HM 170.03 Drag body circular disc

- HM 170.04 Drag body circular ring

- HM 170.05 Drag body square plate

- HM 170.06 Lift body flag

- HM 170.07 Drag body cylinder

- HM 170.08 Drag body streamline body

- HM 170.10 Drag body paraboloid

- HM 170.11 Drag body concave shape

- HM 170.13 Lift body aerofoil NACA 54118

- HM 170.21 Aerofoil with slat and slot flap

- HM 170.22 Pressure distribution on an aerofoil NACA 0015

- HM 170.31 Pitot tube

- HM 170.32 Pitot tube, small

- HM 170.33 Pitotstatic tube

- HM 170.40 Three-component force sensor

- HM 170.50 16 tube manometers, 600mm

- HM 170.52 Fog generator

- HM 170.55 Electronic pressure measurement for HM 170

- HM 170.60 System for data acquisition

Download as PDF

Download this Case Study as a PDF